Creative Consulting & Fabrication

CC&F is a Brooklyn-based company that works with independent artists and designers to produce limited-edition sculpture and furniture, with a focus on mold-making and casting techniques.

My role at CC&F was Lead Fabricator, working directly with the company’s director to develop process plans and schedules for the shop’s many projects, while also handling overall organization and maintenance of the 8,000sf facility.

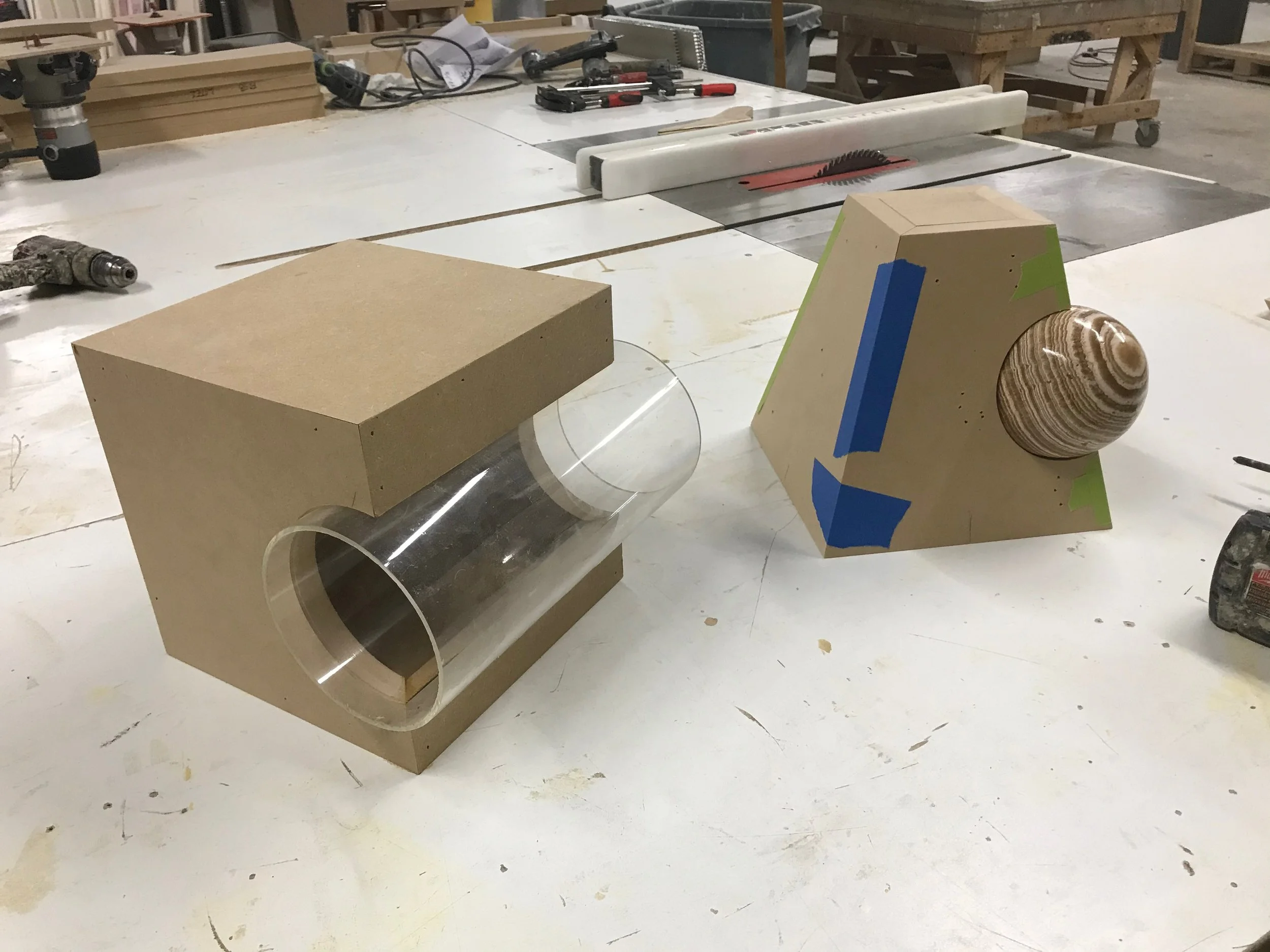

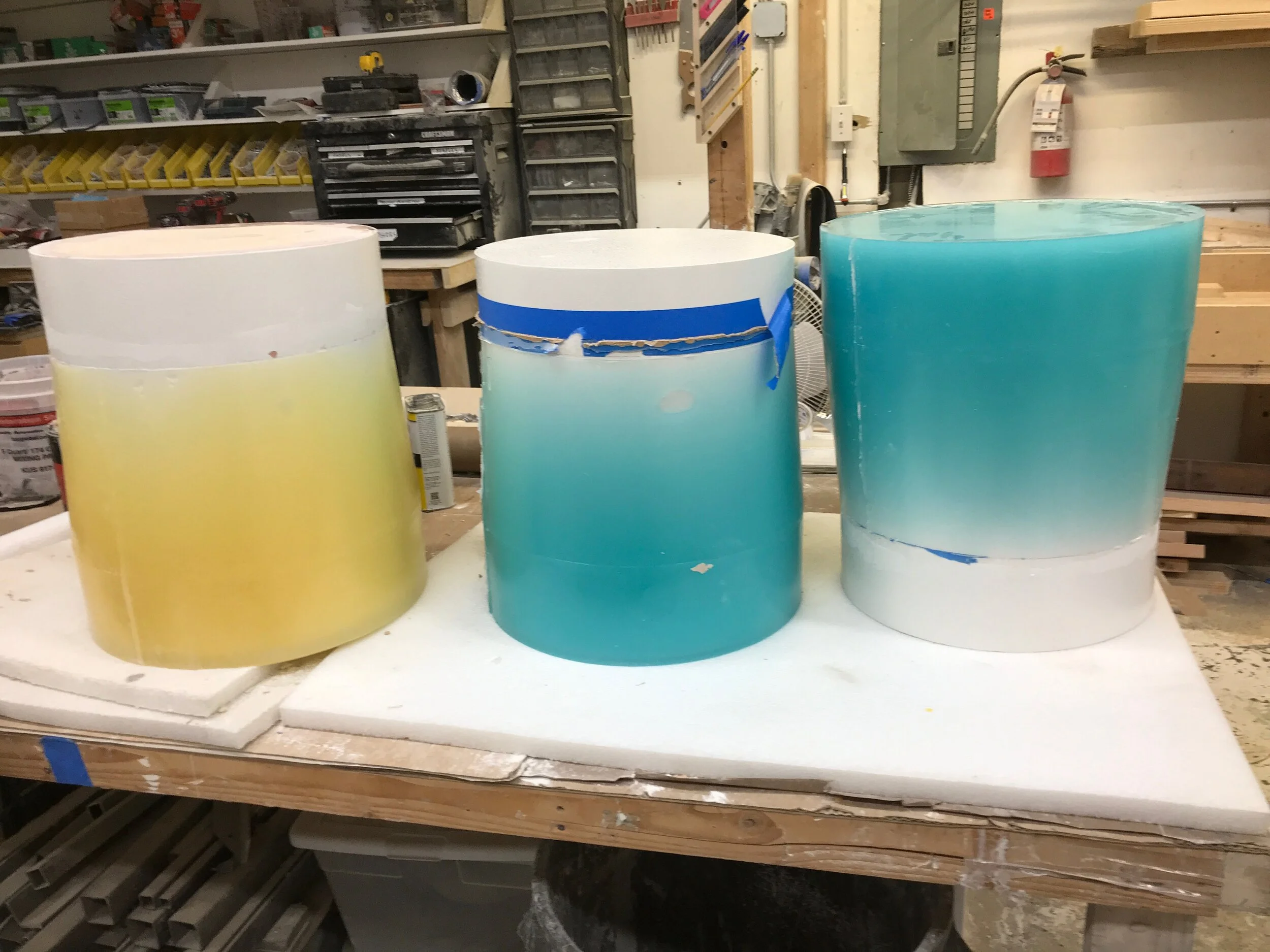

Roto-casters

When we identified a consistent need for producing lightweight, hollow casts I designed and constructed a pair of rotational casting machines, as well as training our staff on their safe and effective operation.

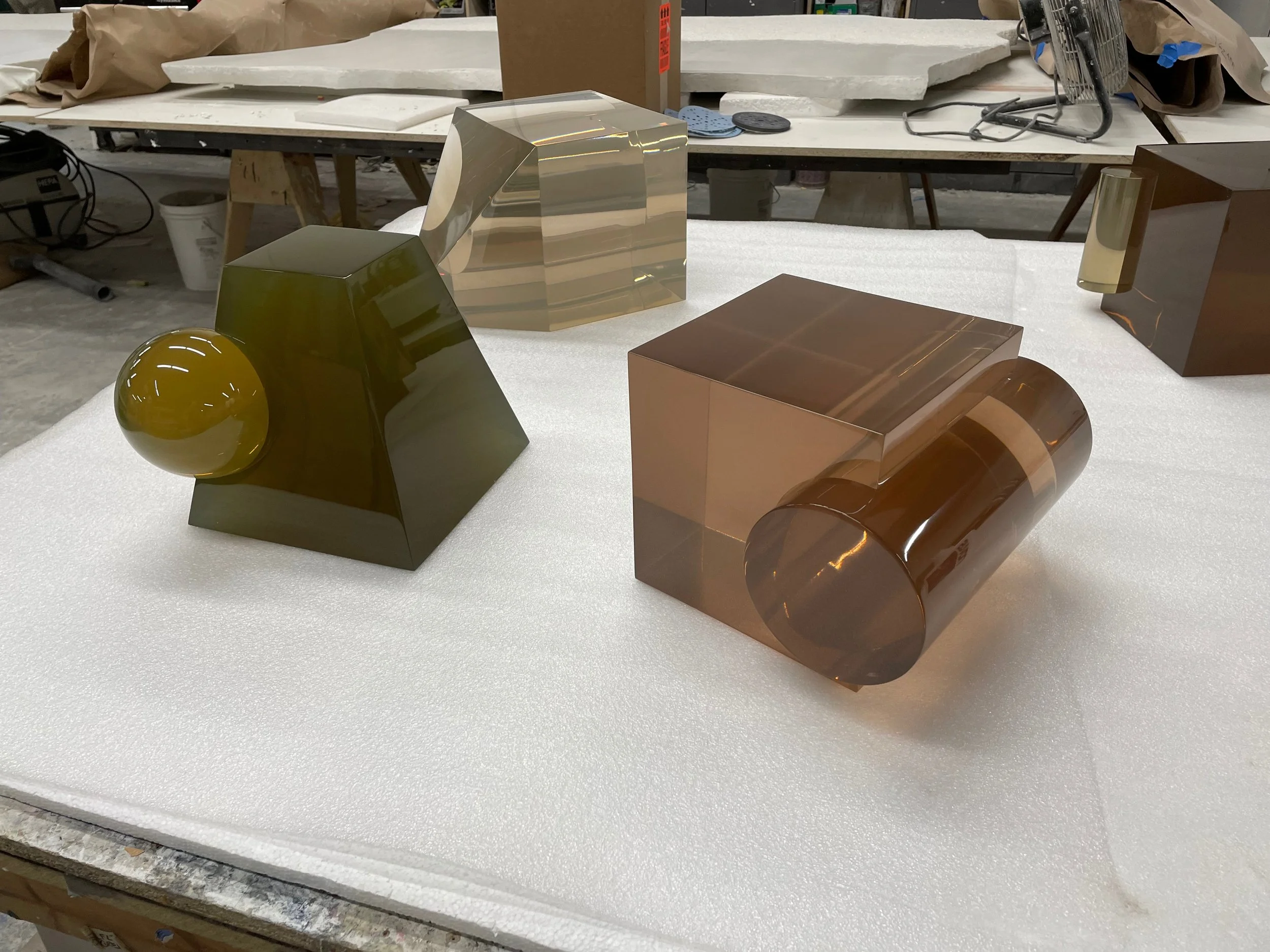

FACTURE STUDIO

In addition to executing sculptural work for clients such as Daniel Arsham and Adam Parker Smith, CC&F also operates Facture Studio — its own in-house brand of resin furniture — the production of which was one of my primary responsibilities.

The central principal of Facture’s work is casting a thin layer of pigmented resin around a white interior core that’s carefully suspended within a mold. A variety of effects are achieved by carefully modifying the depth, transparency, and layering of different colors of resin.

Coffee Table

My first large project working for CC&F, I executed all components of this asymmetrical table which features lots of interesting details such as an “umbrella stand” running all the way through, as well as an integrated foot and protruding lip.

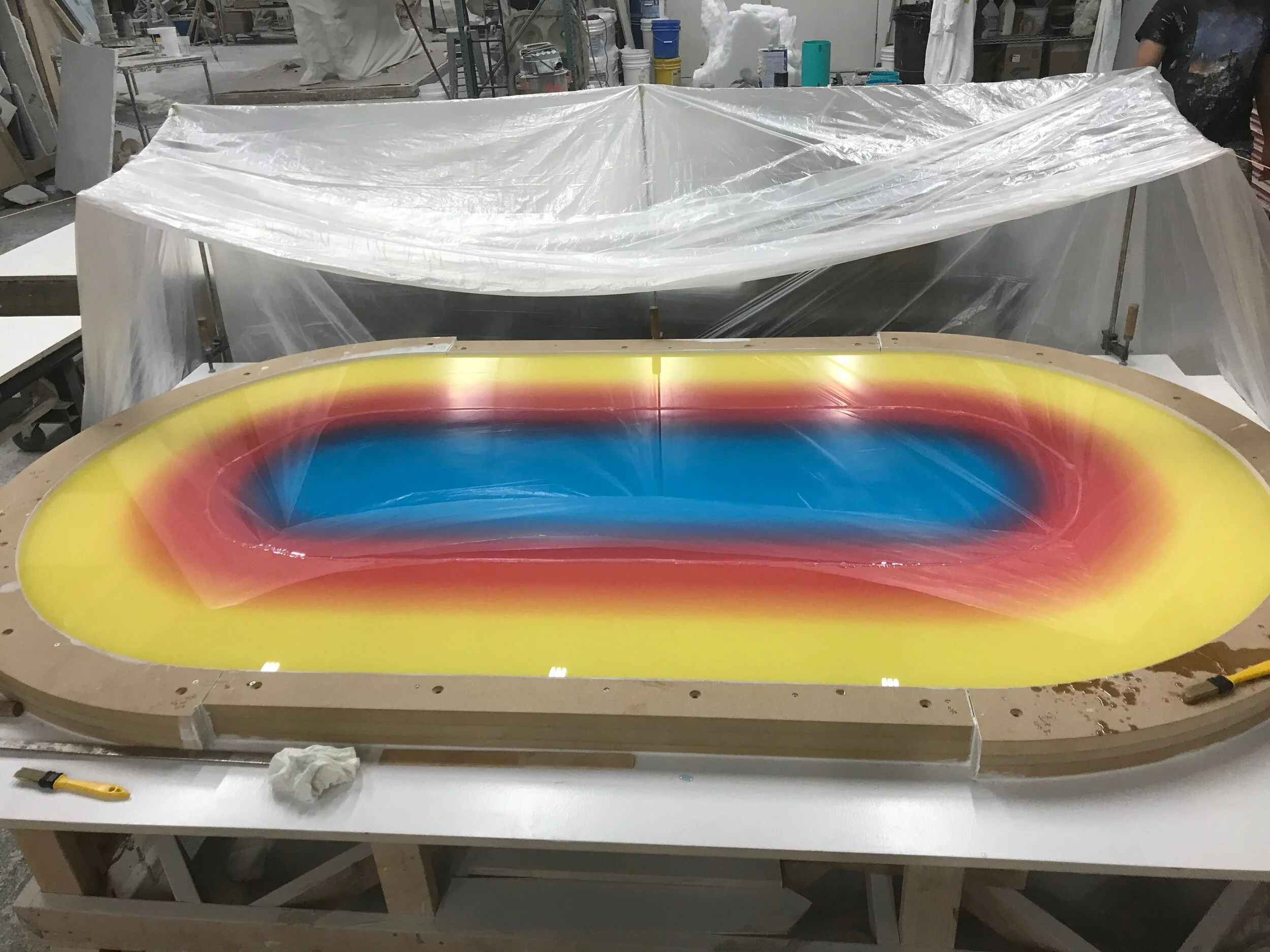

Tri-fade table

This dining table is an example of Facture’s “Fade” technique, where overlapping wedges of color provide a smooth gradient between the two. In this case, the resin for the central band of color was cast first, which I then machined to its final taper using a custom built router jig.

Dining Table set

A more elaborate “Fade” example, I built tapered molds for the initial pours of the seats, while the sun detail on the top was cast flat onto the core using a silicone perimeter mold and then machined to transition from pink to yellow.

bench

This high-polish black bench included a massively over-built steel frame tucked inside its radiused profile, as well as a cast core of resin-stabilized cement, to keep costs down and weight up.

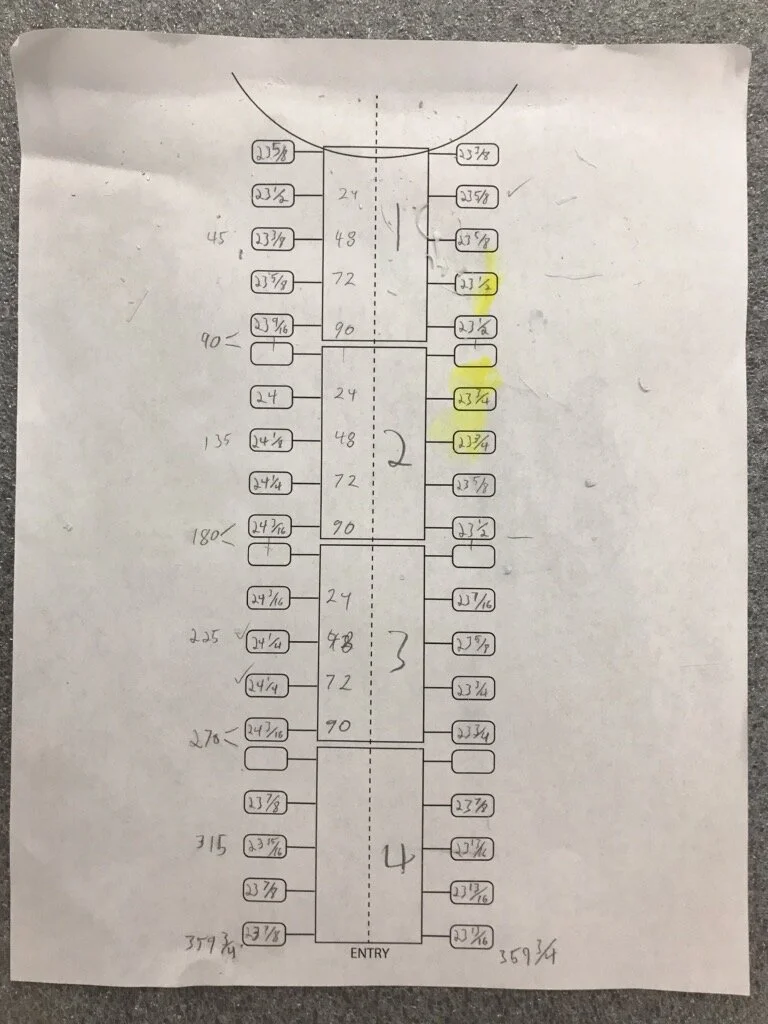

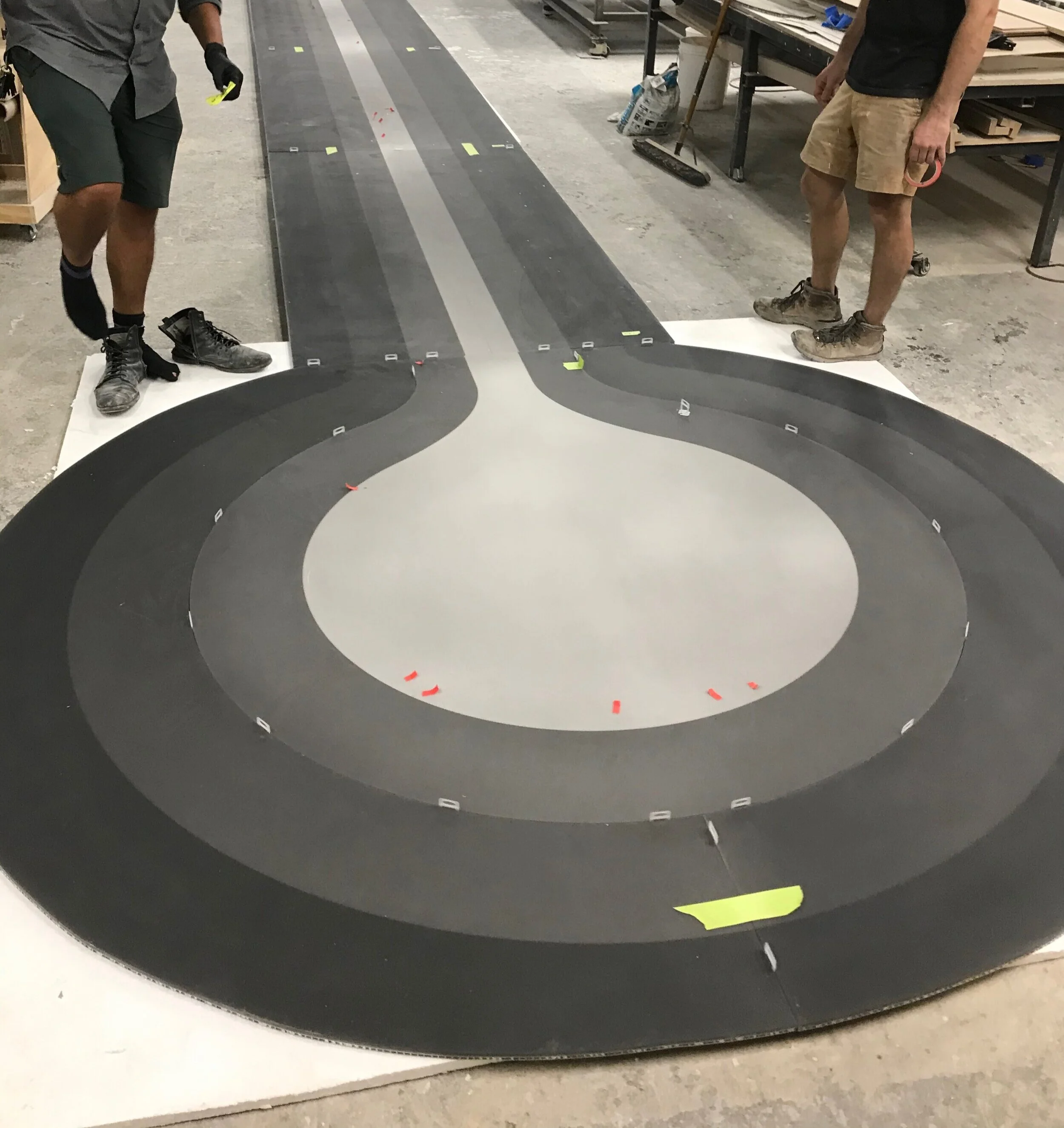

Penthouse Floor

This project featured tiles of resin cast over a honeycomb aluminum substrate. Each panel runs wall-to-wall which meant a meticulous site inspection was required to compensate for any undulations in the building’s construction before the panels arrived for installation. Additionally I hand-shaped a pair of very irregular compound curve thresholds to unite our floor with the surrounding rooms, none of which were at the same grade.

monochrome tub

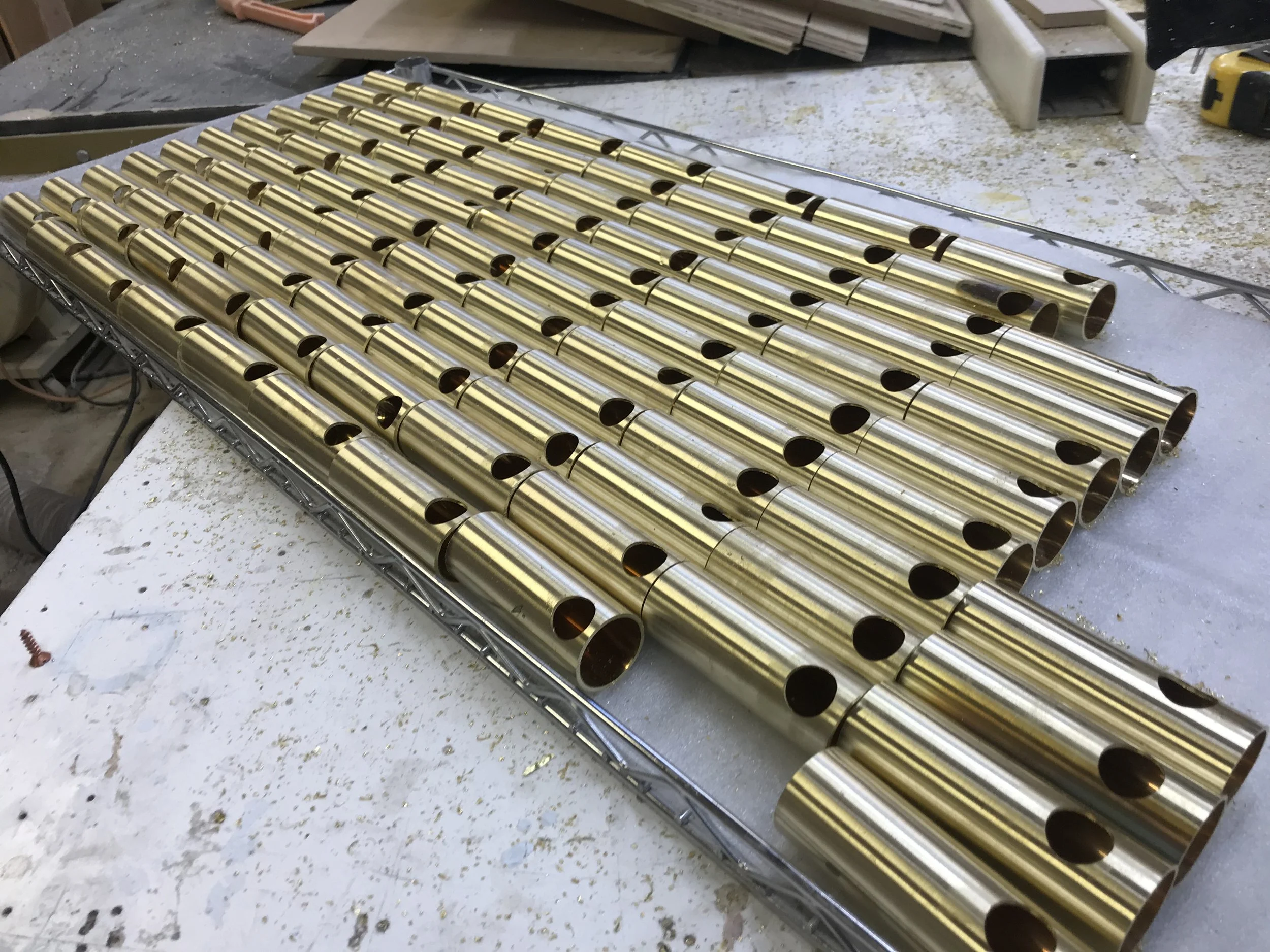

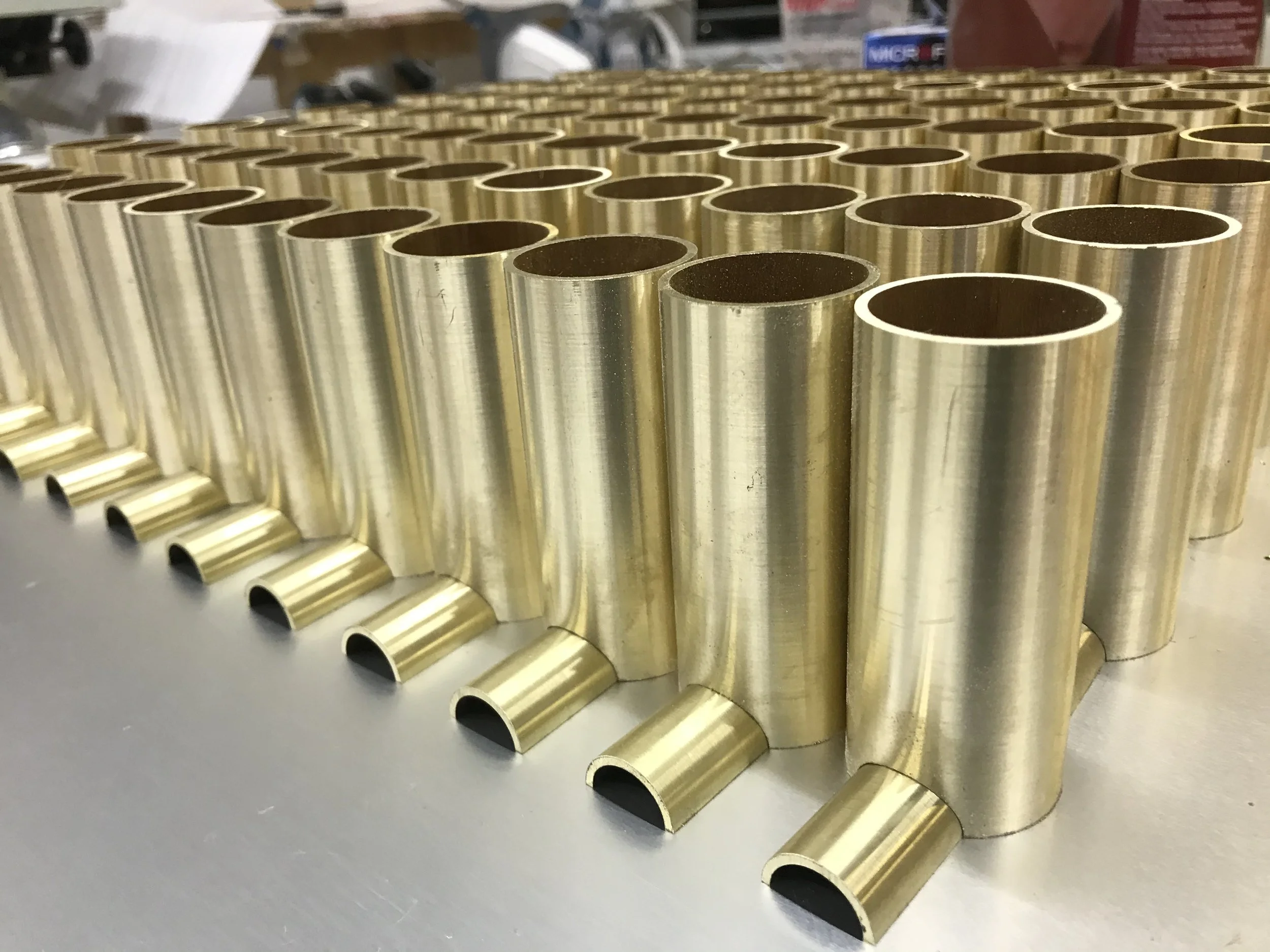

HousePlant

When Seth Rogan decided to collaborate with Facture Studios to release a limited edition of ashtrays based on Seth’s original ceramic designs, my responsibility was to very quickly learn to machine and braze brass in order to produce the 100 cantilevered inserts required for the project.